My gratitude once again to Nicola Higgins for beating me to the punch yet again! I hope she doesn’t mind that I’m totally posting a separate article, but something like this is just too good to reblog! In what is sure to excite Singularitarians and Futurists and scare the holy bejeezus out of technophobes and those fearing the Robopocalypse, a new web-based artificial brain went online recently, allowing robots to share information and seek help whenever they need it.

My gratitude once again to Nicola Higgins for beating me to the punch yet again! I hope she doesn’t mind that I’m totally posting a separate article, but something like this is just too good to reblog! In what is sure to excite Singularitarians and Futurists and scare the holy bejeezus out of technophobes and those fearing the Robopocalypse, a new web-based artificial brain went online recently, allowing robots to share information and seek help whenever they need it.

It’s called Rapyuta (or the The RoboEarth Cloud Engine), a part of the European Robo Earth project that began in 2011 with the hope of standardizing the way robots perceive the human world. Basically, it is an online database that robots can consult in order to get information about their world and help them make sense of their experiences, post-activation.

The name Rapyuta is taken from the Japanese film by Hayao Miyazaki known as Castle in the Sky, and refers to a place where all the robots live. The project, which involves researchers at five separate European research labs, has produced the database as well as software that robot owners can upload to their machines so that they can connect to the system at any time.

The name Rapyuta is taken from the Japanese film by Hayao Miyazaki known as Castle in the Sky, and refers to a place where all the robots live. The project, which involves researchers at five separate European research labs, has produced the database as well as software that robot owners can upload to their machines so that they can connect to the system at any time.

You might say the “brain” is an expression of sympathy for robots, who are no doubt likely to find the world intimidating and confusing once they come online. Now, instead of every robot building up their own idiosyncratic catalog of how to deal with the objects and situations it encounters, Rapyuta would be the place they ask for help when confronted with a novel situation, place or thing.

In addition, the web-based service is able to do complicated computation on behalf of a robot. For example, if it needs to work out how to navigate a room, fold an item of clothing or understand human speech, it can simply do an online consultation rather than try to figure it out on its own. In addition, it is believed that robots will be cheaper thanks to this system since it will mean they won’t need to carry all their processing power on board.

In addition, the web-based service is able to do complicated computation on behalf of a robot. For example, if it needs to work out how to navigate a room, fold an item of clothing or understand human speech, it can simply do an online consultation rather than try to figure it out on its own. In addition, it is believed that robots will be cheaper thanks to this system since it will mean they won’t need to carry all their processing power on board.

Looking ahead, Mohanarajah Gajamohan, technical head of the project at the Swiss Federal Institute of Technology in Zurich, says that the designers believe the system could be particularly useful for drones, self-driving cars or other mobile robots who have to do a lot of number crunching just to get round.

Dr Heico Sandee, Robo Earth program manager at the Dutch University of Technology in Eindhoven, also highlighted the economic benefits of this new concept. “On-board computation reduces mobility and increases cost,” he said, adding that as wireless data speeds increase, more and more robotic thinking could be offloaded to the web.

Dr Heico Sandee, Robo Earth program manager at the Dutch University of Technology in Eindhoven, also highlighted the economic benefits of this new concept. “On-board computation reduces mobility and increases cost,” he said, adding that as wireless data speeds increase, more and more robotic thinking could be offloaded to the web.

But above all, the aim here is about integration. As robots become more and more common and we human beings are forced to live with them amongst us, there could be difficulties. Without access to such a database, those involved in the project and roboticists at large fear that machines will remain on production lines and never live easily alongside humans.

As for those who support and await the Technological Singularity, this could be one such means through which it is achieved. The idea of machines that are capable of network and constantly upgrade their software is a step in the direction of machines that are capable of self-assembling, evolving and upgrading themselves constantly, which will basically result in a rate of progress that we can currently predict.

As for those who support and await the Technological Singularity, this could be one such means through which it is achieved. The idea of machines that are capable of network and constantly upgrade their software is a step in the direction of machines that are capable of self-assembling, evolving and upgrading themselves constantly, which will basically result in a rate of progress that we can currently predict.

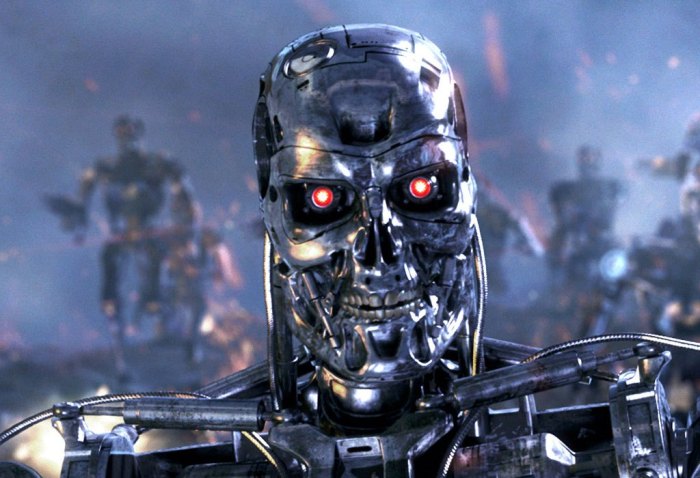

But on the other side of the debate, there are those who say this smacks of a Skynet-like supercomputer that could provide machines with the means to network, grow smarter, and think of ways of overthrowing their human masters. While I don’t consider myself the technophobic sort, I can certainly see how this invention could be perceived that way.

Creating a means for robots to communicate and contribute to a growing sense of knowledge, effectively letting them take ownership of their own world, does seem kinda like the first step in creating a world where robots no longer need human handlers. Then again, if we’re going to be creating AI, we might want to consider treating them like sentient, dignified beings beforehand, and avoiding any “controversy” when they begin to demand them later.

Creating a means for robots to communicate and contribute to a growing sense of knowledge, effectively letting them take ownership of their own world, does seem kinda like the first step in creating a world where robots no longer need human handlers. Then again, if we’re going to be creating AI, we might want to consider treating them like sentient, dignified beings beforehand, and avoiding any “controversy” when they begin to demand them later.

Gotta admit, when it comes to technophobes and paranoiacs, this kind of stuff is certainly fertile territory! For more information on the Rapyuta Engine, simply click here. And may God help us all!

Source: bbc.co.uk

Source: bbc.co.uk