Earlier this year, Distributed Defense became the source of much controversy after they unveiled the world’s first 3-D printed gun. Known as the Liberator, this single-shot weapon was entirely composed of ABS plastic, and was the first weapon that could be created using open-source software and a 3-D printer, giving anyone with access the means to build their own firearms.

Earlier this year, Distributed Defense became the source of much controversy after they unveiled the world’s first 3-D printed gun. Known as the Liberator, this single-shot weapon was entirely composed of ABS plastic, and was the first weapon that could be created using open-source software and a 3-D printer, giving anyone with access the means to build their own firearms.

Predictably, the website was shut down and the design specs were removed, thanks to an injunction filed by the U.S. Department of Defense Trade Control just a few days after the unveiling. However, the issue was far from closed, as the case of Distributed Defense and the Liberator were clearly just a drop in the bucket of a much larger trend. And now, just six months later, the issue is once again rearing its head as the world’s first 3-D printed metal gun was unveiled. Created by the rapid prototyping and 3-D printing company known as Solid Concepts, this 1911 Colt .45 is a major step forward in the realm of weapons that can be built by just about anyone and counted on to remain functional after firing.

And now, just six months later, the issue is once again rearing its head as the world’s first 3-D printed metal gun was unveiled. Created by the rapid prototyping and 3-D printing company known as Solid Concepts, this 1911 Colt .45 is a major step forward in the realm of weapons that can be built by just about anyone and counted on to remain functional after firing.

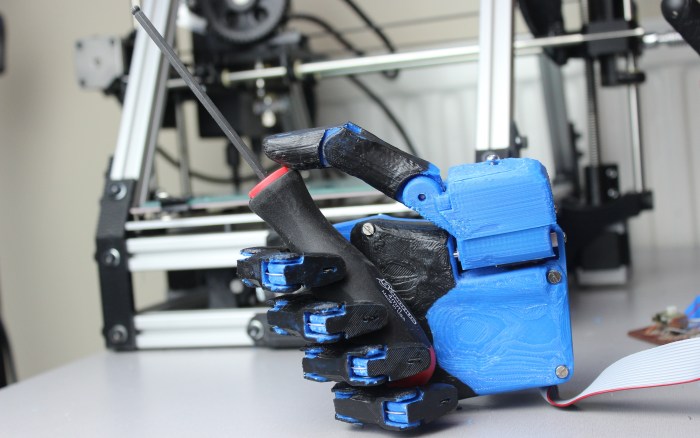

The gun was built using the relatively new process known as Selective Laser Sintering (SLS), a process that combines lasers and powdered metals to create finished products. Basically, a high-powered laser is used to fuse small particles of powder together, layer by layer, until the desired shape is created. In addition to being able to create highly intricate objects, sintering is far more efficient than the machining process.

This latest weapon was also an improvement over the Liberator in that it was able to fire over 50 rounds with considerable accuracy, whereas the Liberator broke down after just a few shots. Made of of over 30 separate 3D printed parts, the gun is composed of stainless steel and Inconel 625 (a nickel-chromium superalloy), consistent with the original Colt design.

This latest weapon was also an improvement over the Liberator in that it was able to fire over 50 rounds with considerable accuracy, whereas the Liberator broke down after just a few shots. Made of of over 30 separate 3D printed parts, the gun is composed of stainless steel and Inconel 625 (a nickel-chromium superalloy), consistent with the original Colt design.

But before people begin to worry that this is bad news, Solid Concepts was quick to point out that the gun was printed using an industrial printer, the price of which is out of range of your average citizen. In addition, the software is not open-source, meaning people can’t simply download it from any 3-D printing website and begin producing their own private arsenal.

Solid Concepts also claims that they produced this weapon to demonstrate how 3-D printing is not just for hobbyists anymore, and how sintering is a viable way to produce delicate, precise, specific consumer and professional grade products. The company said that it is currently the only 3D printing service provider with a federal firearms license, and will be looking to provide printed gun parts for legal gun owners.

Solid Concepts also claims that they produced this weapon to demonstrate how 3-D printing is not just for hobbyists anymore, and how sintering is a viable way to produce delicate, precise, specific consumer and professional grade products. The company said that it is currently the only 3D printing service provider with a federal firearms license, and will be looking to provide printed gun parts for legal gun owners.

Regardless, this story serves as an example of how far the technology of 3-D printing has come in just a short amount of time. From printing models with plastic, the technology is now pushing the boundaries of industrial manufacturing and bioprinting, using everything from steel and titanium to liver and kidney cells.

Give more time and refinement, we could be entering into an age where all consumer products and necessities are created from powder and individual cells, possibly even at the atomic level. For those wondering what the next industrial revolution will look like, I suggest you look no further!

And of course, Solid Concepts captured the test firing of their 1911 Colt on video. Check it out:

Source: extremetech.com